Quartz frit is made of high-purity quartz sand. Quartz sand particles of different sizes are sintered into required shapes to meet different test needs. Our company can provide quartz frit with porosity from 5 microns to 500 microns. We can also produce quartz frit with larger particles according to customer requirements.

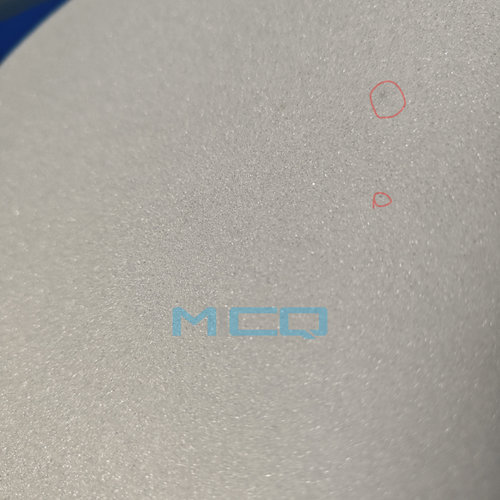

In the process of making quartz frit, we will use graphite as the bearing platform. The quartz fritted discs to be produced will be placed on the graphite bearing table for high-temperature sintering. Since the color of graphite is black, graphite particles are often attached to the quartz frit. Graphite is a material that is more resistant to high temperatures than quartz. It is also often used to process different kinds of quartz glass products. Such black spots are very few in number and often appear on the surface of larger quartz frits. Graphite is an allotrope of carbon. It is a gray-black, opaque solid with stable chemical properties, corrosion resistance, and does not easily react with chemicals such as acids and alkalis. Graphite black spots will not affect the high temperature or acid-base experiments of quartz frit. If you are very concerned about graphite black spots, our company can also replace the graphite material bearing platform with other bearing platforms. For example a ceramic table. This will solve the black spot problem, but it will not completely solve the problem of particles generated by the bearing platform.