Both quartz frit and quartz discs will have dimensional errors after production. However, the dimensional tolerance of quartz frit will be greater. Mainly due to the following three reasons.

The production process of quartz frit is significantly different from that of quartz discs. quartz discs can generally be formed by CNC or laser cutting, so the tolerance will be extremely small. The production of fused quartz frit is generally made by firing molds. The mold itself will have dimensional errors. Therefore, there may also be errors in the size of the sand and the mold.

2. quartz frit itself is made of granular quartz frit. If larger particles are selected for production, the tolerance of the finished product will also change.

3. Quartz frit particles will expand with increasing temperature during the firing process. On the contrary, cooling particles will shrink.

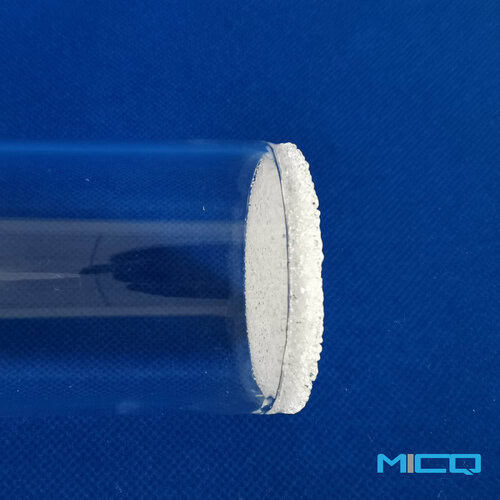

Generally, quartz frit used in the terminal does not require high dimensional errors. Because the use of quartz frit/sinter themselves is only for filtering purposes. In addition, quartz fritted disc are generally accessories for a certain experimental equipment. It is usually installed on a quartz tube, quartz beaker, or quartz funnel. As long as the size of quartz frit itself is suitable for the equipment, it will not affect its use.