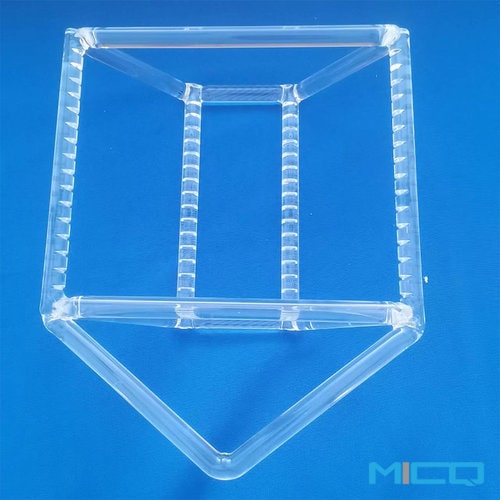

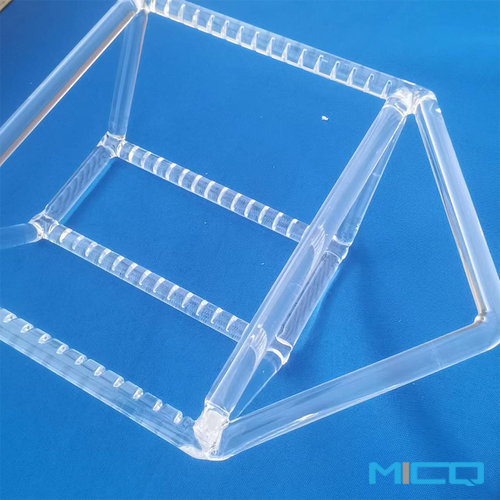

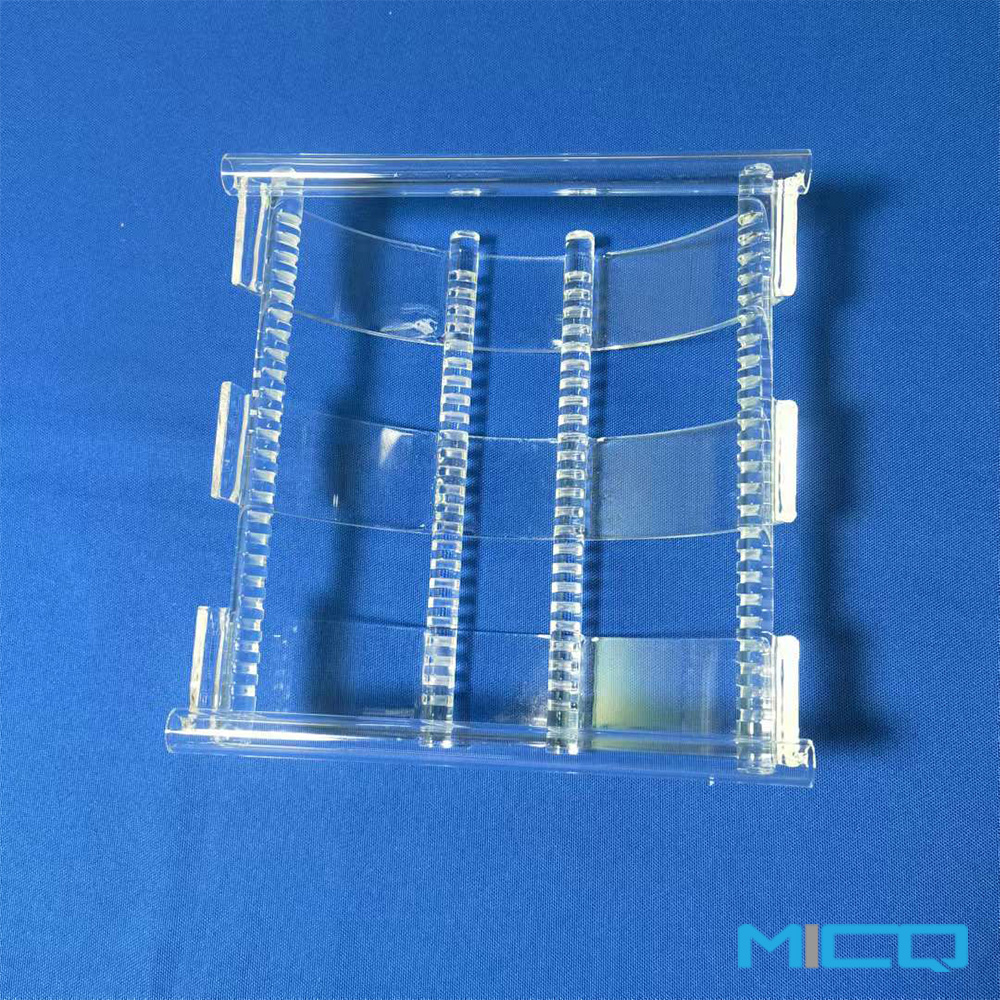

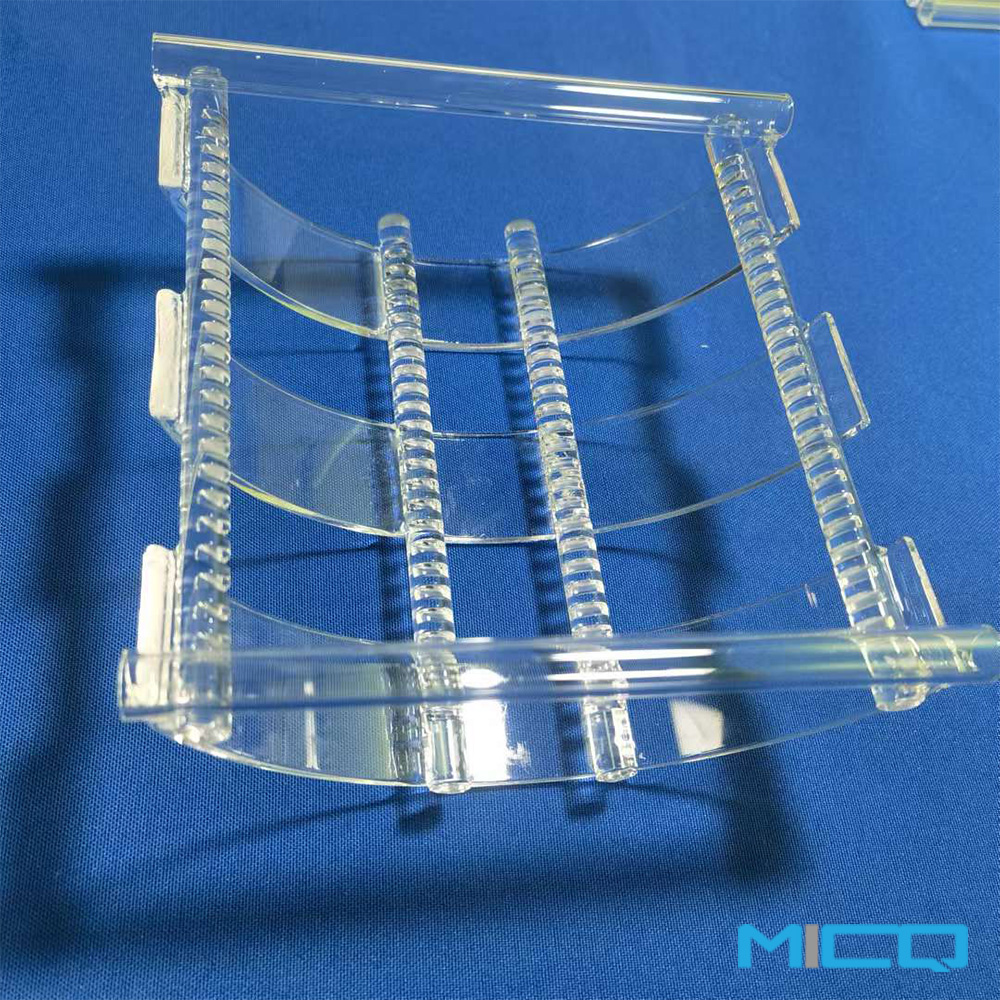

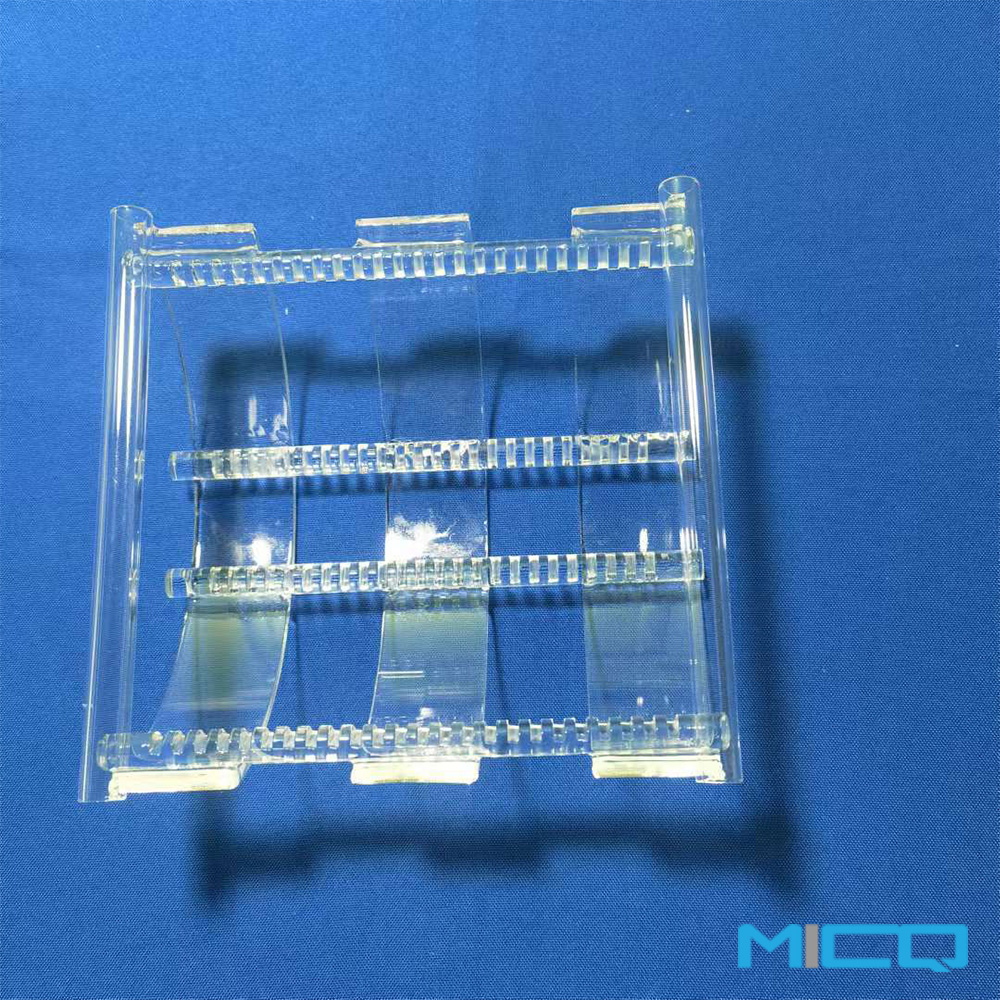

Custom High Purity Semiconductor Fused Quartz Glass Wafer Boats / Wafer Carriers with Different Size & Nos of Slots Available for Diffusion of Wafer Processing

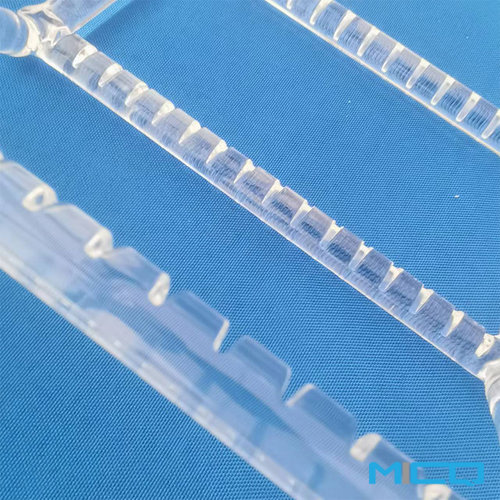

We can customize High Purity Semiconductor Fused Quartz Glass Wafer Boats / Wafer Carriers of any size, including appearance size (conventional dimension is 1 “to 12”) and slots of different widths. The minimum slot width can be less than 1mm. The smaller width of the slots, the more difficult to process, so the higher the cost will be obvious. The common Quartz Glass Wafer Boats’ slots are subject to fire polishing. The fire polishing in slot can make the inner slot wall smooth. During the use of the product, the silicon wafer carriers will not be damaged. For the smaller slots’ width, the higher the machining accuracy is required. Generally, we can control the accuracy tolerance of 1mm of slots width within the range of ± 0.01 to ± 0.03mm. The edges of the slots can also be chamfered slightly.

Another function of the semiconductor quartz boat is to display silicon wafer. At this time, Quartz Glass Wafer Boats / Wafer Carriers should be more concise, so as to show the original appearance of wafer more clearly. High Purity Semiconductor Fused Quartz Glass Wafer Boats can also be used for Diffusion in silicon wafer processing. High Purity Semiconductor Fused Quartz Glass Wafer Boats / Wafer Carriers plays an important role in the semiconductor industry.

When we process semiconductor fused quartz wafer boats, we will customize a specific wafer in advance. This function is to produce more practical and more accurate semiconductor quartz wafer boats. Generally, customers only need to tell us the size and slot numbers of the wafer to be used. Customers can also give us drawings to process required specific and complex semiconductor fused quartz wafer boats. / wafer carriers.

An Introduction of Quartz Boats in Photovoltaic Industry

In the production process of photovoltaic cell, the quartz boat is of pivotal importance. Its principal function is to serve as a carrier for the transportation of silicon wafers in the process of high-temperature diffusion.

Functions of quartz boats

- High-temperature carrying

Quartz boats are employed in high-temperature treatments conducted in an atmosphere comprising high-purity nitrogen, oxygen, or other inert gases, such as during the diffusion stage of phosphorus or boron. These processes represent crucial steps in the manufacture of solar cells, serving to form PN junctions on silicon wafers.

- Precise positioning

The precision design of the slots within the quartz boat guarantees that the silicon wafer remains in its designated position throughout the high-temperature diffusion process, ensuring uniform heating, and consequently, the consistency and efficiency of the final battery performance.

- Avoidingpollution

Because quartz material has exceptional high temperature resistance and chemical stability, it will not cause pollution to silicon wafers, which is conducive to maintaining a high cleanliness of the production environment.

Materials of quartz boats

Quartz boats are usually made of high-purity quartz glass because quartz (SiO₂) exhibits the following characteristics.

- Resistance to high temperatures: The quartz material is capable of functioning for extended periods at temperatures reaching approximately 1200 °C without any deformation or melting, thereby satisfying the requirements for high-temperature diffusion in the production of photovoltaic cells.

- Chemical stability: Quartz exhibits extremely high chemical inertness to most acid and base solutions,as well as many chemicals. This property prevents it from reacting with silicon wafers or introducing impurities during high temperature treatment.

- Low coefficient of thermal expansion: Quartz exhibits a low coefficient of thermal expansion, which enables it to undergo minimal changes in shape and size even when subjected to significant temperature fluctuations. This property is beneficial to maintain precision and repeatability in the process.

- High purity: Quartz boats used in the photovoltaic industry must have a high purity to reduce the presence of any impurity elements that could affect the efficiency of the cell.

Requirements for quartz boats utilization

- Temperature control

The quartz boat is required to function continuously and stably at temperatures reaching thousands of degrees Celsius. Therefore, the material must be capable of withstanding such extreme temperatures without deformation or breakage.

- Cleanliness requirements

The quartz boat must be thoroughly cleaned and dried before use to ensure that it is free of impurities so as not to impair the diffusion effect or stain the surface of the silicon wafer.

- Loading requirements

The silicon wafers should be inserted into the quartz boat in a specific order and direction to ensure that all parts are treated consistently during diffusion.

Care and maintenance

- Cleaning process

Quartz boat cleaning typically employs the ultra-pure water, acid and alkali solutions, or specialized cleaning agents. These are utilized through mechanical scrubbing, ultrasonic cleaning, and other techniques to eliminate residual matter from the boat. Following the cleaning process, it is essential to ensure thorough drying to prevent the occurrence of secondary pollution or corrosion due to the presence of moisture.

- Inspection and repair

A complete inspection of the quartz boat should be carried out regularly. If cracked, damaged or loose parts are found, they should be replaced in a timely manner to prevent debris from falling into the equipment, thereby preventing adverse effects on the equipment itself or the quality of the product.

- Storage management

Following utilization, the quartz boat should be stored in a dry environment, free from dust and external pollution, in order to prevent physical impact or chemical erosion of the quartz boat.

- Life management

Taking into account the actual use of the quartz boat and the degree of loss, it is necessary to replace the quartz boat in a timely manner in order to guarantee the stability of the production process and the quality of the product.

Products Pics

For prompt quotation, please contact us at below form.

Application:

Chemical Industries

Electric Light Source

Laboratories

Medical equipment

Metallurgy

Optical

Photovoltaic

Photo communications

Research

Schools

Semiconductor

Solar