Custom Fused Quartz Glass Balls/Beads

Custom Fused Quartz Glass Beads/Balls

Fused silica glass material can be used to process various shapes of quartz glass products. Quartz glass ball is one of them. Because of quartz glass can withstand high temperature and most strong acids and alkalis, fused quartz balls can be used as filter media to filter strong acids and alkalis. Our company can process various specifications of quartz glass beads. Maximum diameter can reach 50mm or more, and the minimum diameter is generally 2-3mm. How is fused silica beads processed? If a single bead is polished manually, it will be a huge workload for quartz balls with smaller diameters. We use specific abrasive tools to grind it out on the machine. The polished quartz beads all have a frosted surface. We use oxyhydrogen flame to fire polish in batches. This fire polishing must be carried out in the quartz bead with movement to achieve uniform polishing. Our company can accept orders for quartz glass beads/balls with a minimum order quantity of 1kg. Welcome to get your inquiries.

Our company can provide various specifications of quartz glass beads/balls. We can make regular quartz glass balls with diameter of 3mm or more. If there are special requirements, quartz balls smaller than 3mm can also be customized. The application fields of quartz balls are very extensive. The common use is as a filter element for filtration. Due to its acid and alkali resistance, quartz glass beads can filter acidic and alkaline solutions.

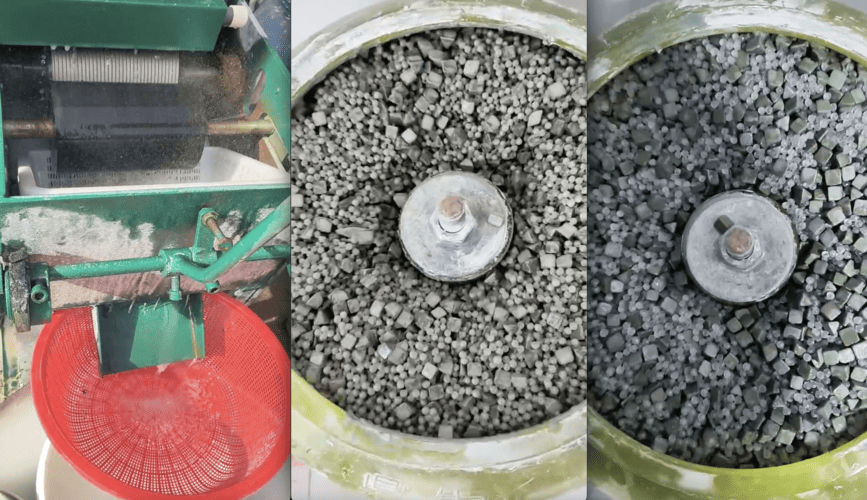

The production process of quartz glass beads/balls.

1. Forming Coarse Quartz Balls/Beads

On the premise of determining the specifications, the first step is to choose suitable quartz rods as processing material for fused quartz balls. Usually, the outer diameter of selected quartz raw material rod is 1 to 2 millimeters larger than that of quartz beads/balls. Then put quartz rods into a rough grinder for cutting and grind into shape.

2. Polishing

Polishing is the longest step in the process of processing quartz beads. Put the roughly ground quartz beads/balls into the polishing shaker. Add polishing sand again. The polishing process takes approximately 12 hours for once. This requires seven to eight repetitions times.

3. Screening Specifications

Polished quartz glass beads/balls often have differences in size. Therefore, it is necessary to screen the specifications of the mesh.

4. Quality Inspection

Qualified quartz glass balls must be bright and accurately sized. There must be no damage, otherwise it will affect future use.

Processing

Froming

Rough Grinding

Fine Grinding

Products Pics

For prompt quotation, please contact us at below form.

Application:

Chemical Industries

Electric Light Source

Laboratories

Medical equipment

Metallurgy

Optical

Photovoltaic

Photo communications

Research

Schools

Semiconductor

Solar