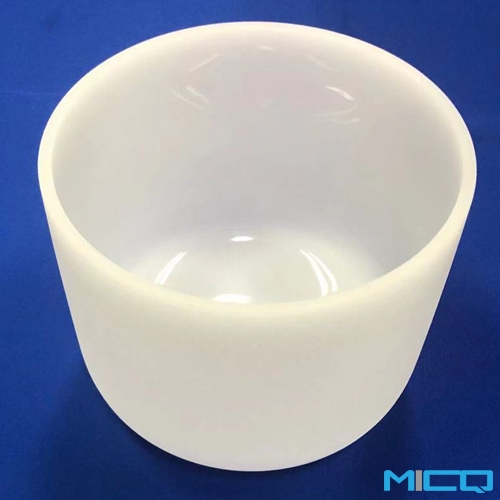

Semiconductor Opaque Fused Silica Electric Arc Quartz Crucible

SiO2 Purity: 99.99%

Welting Point: 1750 ℃

Working Temperature: 1100℃~1450 ℃

Use: monocrystalline silicon, heating container in semiconductor

Dimensions: 6″, 7″, 8″, 9″, 10″, 11″, 12″, 13″, 14″, 16″, 18″, 20″, 22″, 24″, customization available

8″-D203mm x H153mm(±3mm)

10″-D254mm x H178mm(±3mm)

12″-D305mm x H228mm(±3mm)

14″-D355mm x H254mm(±3mm)

16″-D404mm x H305mm(±3mm)

18″-D457mm x H355mm(±3mm)

20″-D508mm x H381mm(±3mm)

22″-D558mm x H381mm(±3mm)

24″-D610mm x H381mm(±3mm)

Any other Dimensions in Customizalbe

Description

Semiconductor Opaque quartz crucible made by electric arc method is an indispensable basic material for producing monocrystalline silicon and large scale integrated circuits.

Semiconductor Quartz crucible can be used around 1400 C degrees. It can be divided into two types: clear and opaque. The semiconductor opaque quartz crucible by the arc method is an essential basic material for the development of large-scale integrated circuits. Clear semiconductor quartz crucibles are being replaced by opaque semiconductor crucibles because of its processing method. Nowadays, semiconductor electric arc quartz crucibles are becoming a main stream in the developed countries of semiconductor industry. It has a lot of advantages like high purity, high temperature resistance, large size, high precision, good heat preservation, energy saving and stable quality.

Application of Arc Quartz Crucible:

1. Drawing of monocrystalline silicon

2. Sintering container of color phosphor

3. Crucible for color glass melting

At present, the world’s silicon single crystal production is mainly used by arc crucible.

Processing: project production produce for semiconductor quartz round crucible , the main process steps include mold filling,

melting furnace to melt , finished products, dimensional inspection, pickling,

water washing, ultrasonic cleaning, coating barium, packaging into the warehouse

Feeding: add the required high-purity quartz sand to the graphite mold, put the mold into the melting furnace

Melting: first to vacuuming, and then use three graphite electrodes to generat electric arc , melting stage temperature of about 1700 degrees Celsius.

the part of quartz sand dust is brought out in this vacuuming process, it need to be collected and treated

Finished product: after 30 to 40 minutes of melting phase, the arc will be closed, the mold exit furnace.

Size inspection:Use calipers and calipers to check the size of products ,and be into the next process.

Sandblasting: use spray gun to spray quartz sand on the surface, use to remove the impurity on the surface

spewing sand collected by the dust collector after reusing, manual operation, set up a special sandblasting room.

Cutting: After the crucible melting is completed, Take the mould with crucible out of the melting furnace.

The worker gently taps the outer surface of the mould with a hammer to separate the crucible from the mould

. The mold can be reused. In general, the mold can be used over ten times.

Scrap treatment when graphite molds are severely cracked or deformed.

Inspection: manual inspection on the size of the crucible specifications

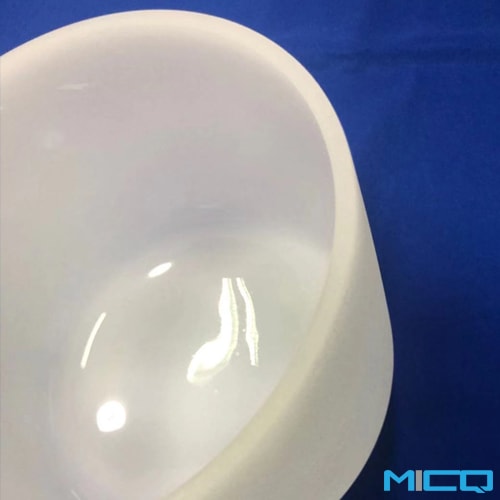

Cleaning: First pickling, the crucibles were immersed (6% to 8%) in HF acid wash tank, and then remove cricibles to clean water for washing,

at last high-pressure cleaning and ultrasonic cleaning, remove the surface residual ions.

Barium coating: Dissolve barium hydroxide powder into water, put cricibles into the Barium coater ,

apply barium hydroxide evenly on the surface of the inside crucible.

Packing and Stocking

For prompt quotation, please contact us at below form.

Application:

Chemical Industries

Electric Light Source

Laboratories

Medical equipment

Metallurgy

Optical

Photovoltaic

Photo communications

Research

Schools

Semiconductor

Solar