High Purity Fused Quartz Frits/Porous Sintered Filter/Fritted Glass Discs/Quartz Glass Sintered

High Purity Fused Quartz Frits/Porous Sintered Filter/Fritted Glass Discs/Quartz Glass Sintered of our company are made of high purity fused quartz sand with content SiO 2 > 99.99% and high temperature resistance up to 1400 ℃. Then it has even porosity and is durable. It is widely used in various scientific research institutions, university laboratories and other related industrial fields. We are fully capable of producing all types of fused quartz frits with different porosity(G00 to G5), sizes and shapes(round, square, cylindrical) according to your customized requirements. Also, depending on our ability to produce other types of quartz glass products, we would fabricate quartz frits into other quartz glass instruments as a complete product to help our end customers solving their use problems.

You can online purchase regular Quartz Fritted Disc at micqstore.com. If any question you can ask for, just to email us: sales@micquartz.com

Raw material source:

High purity fused quartz sand (SiO2 content more than 99.99%). This is not natural quartz sand. Because natural quartz sand contains too many other impurities, for this raw materials cannot be used to produce quartz frits. Quartz sand we use to produce Fritted Sinter come from purifying natural quartz ore, and high-purity fused quartz is obtained after smelting and purification. Fused quartz is crushed before particle screening. Therefore, the particle size determines the porosity of fritted filter produced in the future.

REFERENCE RANGE OF DIMENSIONS FOR CUSTOMIZATION(EX: ROUND SHAPE) |

|||

ITEMS |

POROSITY |

THICKNESS(mm) |

DIAMETER(mm) |

G00 |

250~550microns |

15~300 |

4~500 |

G0 |

160~250microns |

10~300 |

4~500 |

G1 |

100~160microns |

3~300 |

2~400 |

G2 |

40~100microns |

3~300 |

2~400 |

G3 |

16~40microns |

3~300 |

2~400 |

G4 |

10~16microns |

3~300 |

2~400 |

G5 |

5~10microns |

3~300 |

2~400 |

How to determine porosity?

The determination of porosity mainly depends on the particle size of fused quartz sand. In the process of producing quartz frits, the degree of firing will also affect the porosity to a certain extent. Before the production of sintered filter, we have proportioned various pore standards that corresponding to how much size of particles, then molding, extrusion, firing to frit.

Approximate application of various porosity:

G00(250-550 μm) : liquid and gas filtration

G0(160-250 μm) : gas filtration, gas shunting in liquid under low pressure, filtration of very coarse sediment

G1(100-160 μm): coarse filtration, coarse sediment filtration, gas filtration in liquid, slow flow of liquid, filtration of coarse gas, used for making coarse mineral extraction device, and gel filtration substrate with loose filter layer.

G2(40-100 μm) : pre fine filtration, used for preparation of crystalline sediment, mercury filtration

G3(16-40 μm) : analytical filtration, analysis of medium and fine precipitates, preparation of fine precipitates, cellulose chemical filtration, fine gas filtration, fine mineral extraction device,

G4(10-16 μm) Analysis: fine filtration, analysis of very fine sediment (e.g. BaSO4, Cu2O), analysis of sediment with appropriate fineness, mercury check valve and stop valve

G5(5-10 μm) : Used for the analysis of ultra-fine substances. It is usually close to the effect of G4.

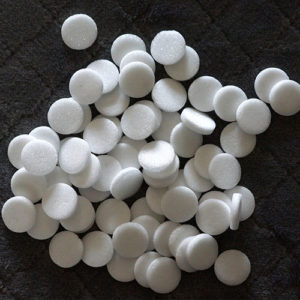

Image for Various Porosity Difference of Quartz Frits

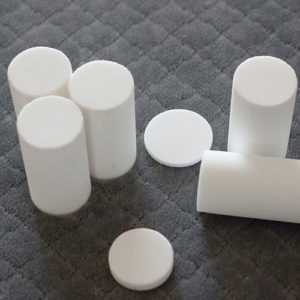

Various Shapes of Quartz Frits

You can custom various shapes or size of High Purity Fused Quartz Frits/Quartz Filter/Quartz Frited Discs/Quartz Sinters

from us. Only click to contact us or fill the below of contact form.

Types of quartz frits/porous rit/glass sintered filter we can make:

Large size quartz frits

Rectangular quartz porous frits

Cylindrical quartz sintered frits

Square sintered filter

Round fritted disc

For prompt quotation, please contact us at below form.

Application:

Chemical Industries

Electric Light Source

Laboratories

Medical equipment

Metallurgy

Optical

Photovoltaic

Photo communications

Research

Schools

Semiconductor

Solar