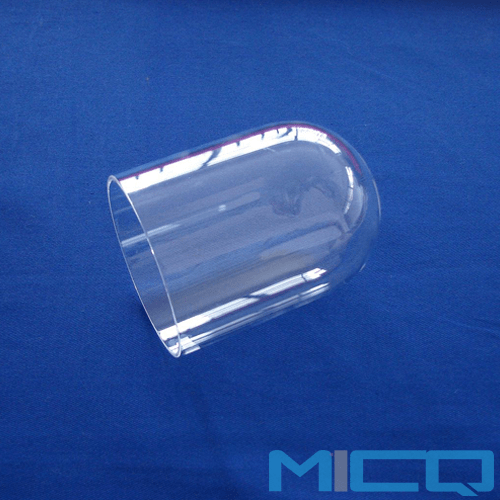

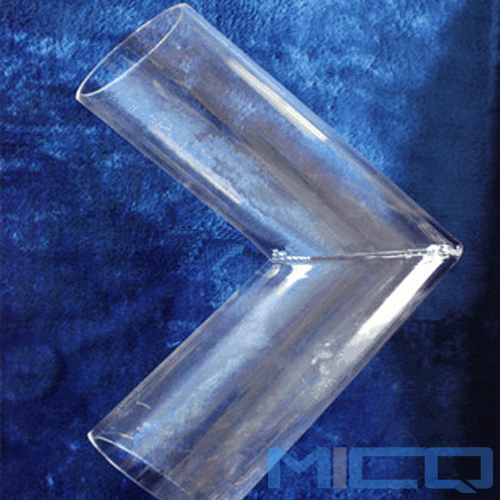

Type: Custom Various Standard Quartz Glass Taper Joints

Material: High Fused Quartz(99.998% SiO2)

Packing: Wooden Case / Carton, Plastic Foam into Packing

Shipping: Free by Sea, Cheap Freight by Express to Door

Item NO.: 2411272

MOQ: No limited

Custom Different type Available

Custom Various Standard Quartz Glass Taper Joints

Description

Custom Various Standard Quartz Glass Taper Joints

The use of quartz standard taper joints is very extensive. Commonly used to connect various experimental instruments. It can also be used as a sealing port for making various experimental vessels. Quartz standard taper joints usually presents a frosted surface. This surface can seal various volatile liquids and even gases.

1.The following is the processing flow of quartz standard taper joint:

The grinding of quartz standard mouth can be done using sandpaper, grinding stone or professional abrasives.

2.Sandpaper: Quartz glass is a relatively hard material that can be polished with sandpaper. Choose finer sandpaper, such as size 320 or above, to avoid scratching or damaging the surface of quartz glass with coarse sandpaper. Gently rubbing the surface of quartz glass with sandpaper can achieve the grinding effect.

3.Grinding stone: Grinding stone is another effective tool, especially for rough quartz glass surfaces. After adding water to the grinding stone, rubbing it on the surface of quartz glass can remove surface stains or small scratches. When using a grinding stone, pay attention to controlling the force to avoid damage to the quartz glass caused by excessive force.

Professional abrasives: For situations that require higher precision grinding, professional quartz glass abrasives can be chosen. These abrasives are usually used together with polishing machines to more accurately remove defects on the surface of quartz glass, while protecting the original luster of quartz glass. When using, follow the product instructions and generally perform rough grinding first, followed by fine grinding and polishing.

Fused Quartz Glass Features:

Fused quartz glass is a special industrial glass made of silicon dioxide. It is a very good basic material. Quartz glass has a series of excellent physical and chemical properties.

1. High temperature resistance. The softening point of fused quartz glass is about 1730℃ and can be used for long time working under 1100℃~1250℃. And working at 1450℃ in a short time.

2. Corrosion resistance. In addition to hydrofluoric acid, fused quartz glass is inert to other acids. Its acid resistance is 30 times as ceramic, 150 times as stainless steel. Especially, any other material cannot make a comparison with chemical stability of fused quartz at high temperature

3. The thermal stability is good. Thermal expansion coefficient is extremely small. And it can withstand severe temperature changes such that heating up to 1100℃ and putting it in normal temperature water will not crack.

4. The light transmittance is good. Quartz glass has good transmittance in the whole spectral band from ultraviolet to infrared. The transmittance of the visible light is above 95%. Especially in the ultraviolet spectrum band and the maximum transmittance is over 85%.

5. The electrical insulation performance is good. Resistance value of quartz glass equaling to 10000 times of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even under high temperature.

As a leading China fused quartz glass supplier and manufacturer, we are providing best price as well as quality for all kinds of customized fused quartz products. We are also willing to look for long term partners who are a distributor or wholesaler specialized in fused quartz glass in local.

For prompt quotation, please contact us at below form.

LEAVE A MESSAGE

Fused quartz glasses have the excellent properties for their following features:

- High working temperature

- Thermal shock resistance

- High electrical insulation

- Optical transparency

- Chemical inertness