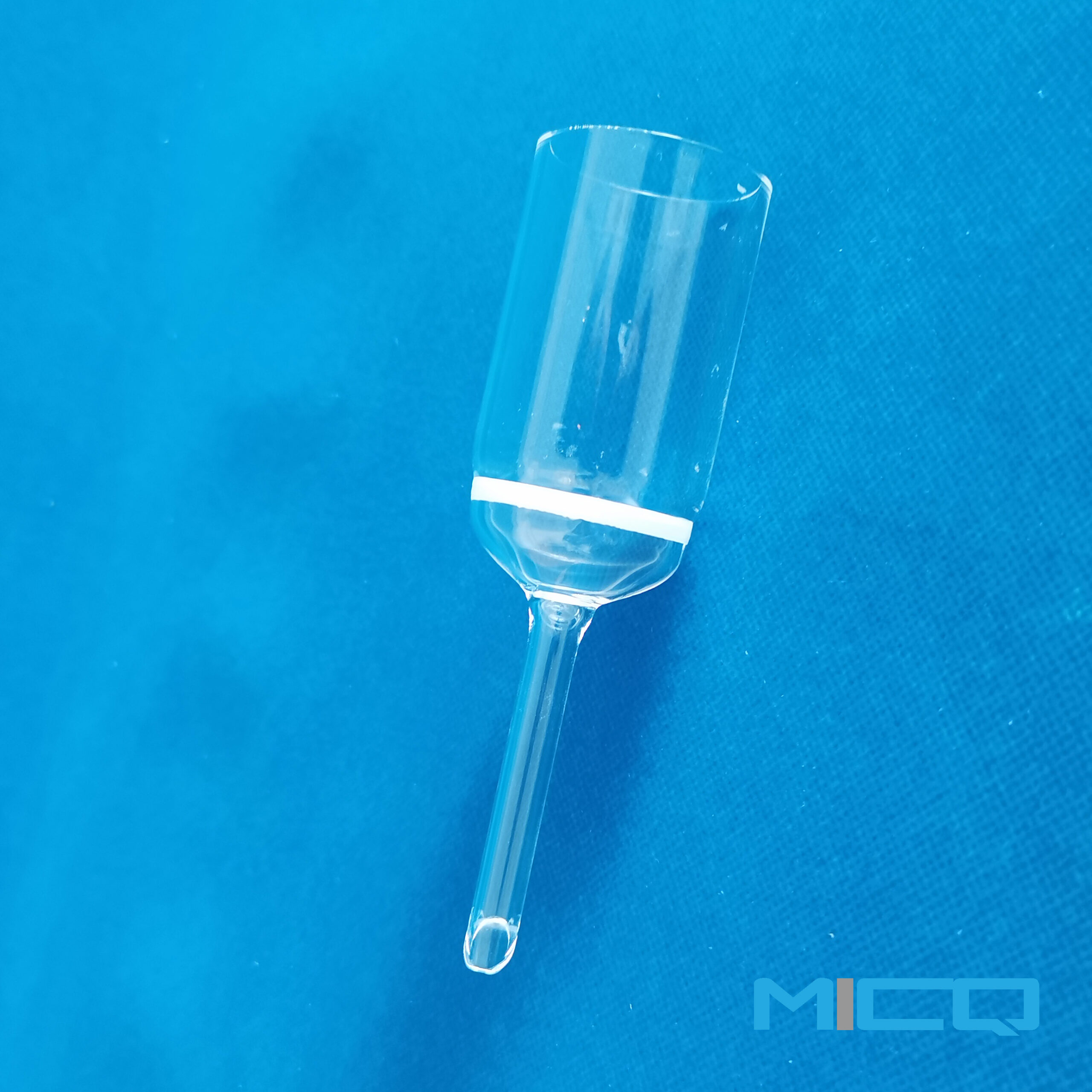

Fused Quartz Frits/Porous Sintered Filter/Fritted Glass Discs/Quartz Glass Sintered / Quartz Filtration

The main factors that customers consider when choosing quartz Frits/Sinters are the purity of raw materials, the tolerance of finished products and the accuracy of porosity.

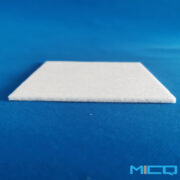

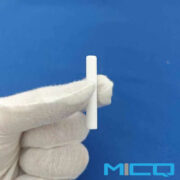

We produce quartz sintered discs using high-purity quartz sand raw materials. Therefore, there are almost no other impurities visible on the surface of finished quartz sinters. This raw material fully meets the testing requirements of various acidic and alkaline experiments.

We also have our own testing standards for controlling the porosity of quartz frits. Such standards are already in line with international standards. Firstly, we will choose multiple different particle sizes of quartz sand. Classify these quartz sands based on their particle size. Then make it into the same size specification. Perform gas and liquid filtration tests on each specification. Then set quartz sand raw materials with different porosities according to the filtering standards. For example, G00~G5.

Regarding tolerance control, we conduct precise testing of molds during the production of finished products. The cost tolerance for conventional sized quartz sinters is ± 0.5mm. For small-sized quartz fritted disc, we can control within ±0.2-0.3mm.