Description

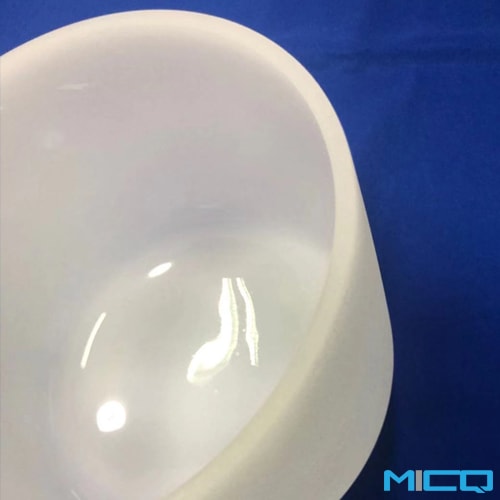

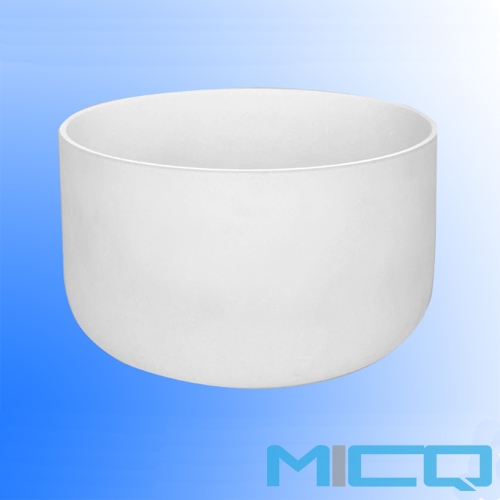

Opaque Fused Silica Electric Arc Quartz Crucible

Opaque quartz crucible made by electric arc method is an indispensable basic material for producing large diameter single crystal silicon and large scale integrated circuits.

- The effectsof quartz crucible crystallization

Crucible crystallization involves the transformation of the transparent quartz layer from a glass phase to a cristobalite, resulting in structural damage and coating degradation within the crucible. This transformation may also lead to reactions between the bubble layer and molten silicon, causing granular silicon oxide to enter the molten silicon and flow towards the crystal growth front. Such phenomena can result in the loss of single crystal structure of silicon single crystal, commonly known as long crystal break line. Furthermore, crystallization leads to a reduction in original thickness of the quartz crucible, weakening its strength and altering its structure, shape, and density, ultimately leading to the fragmentation and mechanical failure of the quartz crucible.

When serious crystallization occurs, quartz will be prone to detachment, which can impact crystal pulling. However, a small amount of crystallization enhances the stability of the crucible surface, thereby facilitating crystal pulling (Some analyses suggest that doping BaCO3 can promote the formation of tiny and dense cristobalite crystals on the inner wall of the crucible. This dense crystal layer on the inner wall is less susceptible to erosion and spalling by silicon melt. Even if tiny particles do spall off, they are more easily melted in high-temperature melt), effectively reducing oxygen content.

In cases where the quartz crucible is corroded by heavy metals, black spots of crystallization may appear. This phenomenon arises from heavy metals significantly lowering the melting point of quartz and altering impermeability between silicon and quartz, leading to numerous black spots on the quartz crucible.

- The reasons of quartz crucible crystallization

- Lack of standardized operation

Crystallization primarily occurs on the external surface of the crucible, followed by the internal defects of the crucible, because these areas are susceptible to staining, which will result in the partial aggregation of impurity ions. In particular, the entrance of alkali metal ions, including potassium (K), sodium (Na), and lithium (Li), as well as alkali earth metal ions, including calcium (Ca) and magnesium (Mg), will result in a reduction in the viscosity of the crucible, thereby accelerating the loss of penetration and ultimately leading to the crystallization of the quartz crucible.

In the manufacturing process, due to the lack of standardized operation, (Impurities such as sweat, saliva, oil and dust enter the crucible during the quartz crucible inspection and loading process, or the crucible is contaminated during its production, cleaning and packaging process.) the crystallization of the crucible will inevitably occur. The contamination of quartz crucibles contains a significant quantity of alkali metal ions, which are the primary factor responsible for the crystallization of quartz crucibles.

- Poor quality of the quartz crucible itself

The geometric dimensions and external appearance of the quartz crucible are determined by the production process; however, the purity of the quartz crucible is dependent upon the quality of the raw material. The raw material used in the production of quartz crucibles, namely high-purity quartz sand, necessitates a high purity, a favourable consistency, and a uniform particle size distribution. The presence of harmful components in the quartz crucible can have a detrimental impact on its functionality in terms of melting and temperature resistance, and can even result in bubbles, colored spots, peeling, etc., which seriously affect the quality of the quartz crucible.

For example, the purity of the drawn single crystalline silicon will be adversely affected by an excess Al content of the raw material; the softening temperature of the quartz crucible will be decreased by a high concentration of Na, K and Li; and the colour spots will appear due to a high content of Cu, Mn and Fe. In addition, the high content of harmful elements will also give rise to the formation of bubbles, white spots and other defects, which will result in a reduction in the transparency of the quartz crucible and, in severe cases, an alteration in its shape. Therefore, when this kind of quartz crucible is used, it will react with molten silicon at high temperatures, leading to serious crystallization of quartz crucible. This, in turn, can result in the leakage of silicon, and has a significant impact on the production of single crystalline silicon rods.

If crystallization occurs on the inner surface of the crucible, the viscosity of the crucible will decrease following the partial aggregation of the impurity ions. This results in the crystallization layer becoming too thick and prone to detachment, thereby preventing the continued pulling of the silicon single crystal rod. If the crystallization is close to the outer wall of of the crucible, it is easy to form a bulge at the bottom or corner.

- Influence of external factors

The crucible is insufficiently calcined or is utilized after being contaminated; the raw materials used for crystal pulling are of low purity, containing excessive impurities (acid, alkali ion residue); or the cleaning process is imperfect. All of these factors significantly impacts the normal use of the crucible, which primarily manifests in a susceptibility to severe crystallization of the crucible. Furthermore, excessive melting temperature or repeated melting cycles cause prolonged exposure of the quartz crucible to high temperatures, which will also intensify the its degree of crystallization.

- How to prevent serious crystallization of quartz crucible

- The entire process of single crystal drawing should beconducted in strict accordance with the process specification standard.

- Quartz crucible manufacturersshould guarantee that the production of crucibles, from the initial material to the final product, adheres to the established quality requirements.

- The purity of the raw materials used for crystal pulling must meet the requirements of standard production, and the cleaning quality of the raw materials must also meet the process requirements to avoid acid and alkali residue on the surface of the silicon material.

- New graphite devices, such as the graphite crucible, must undergo a thorough calcination process at elevated temperatures to remove any residual ash powder and other impurities before being put into use.

- During the melting process, the optimal melting temperature can be selected in order to decreasethe degree of crystalliz

Fused Quartz Glass Features:

Fused quartz glass is a special industrial glass made of silicon dioxide. It is a very good basic material. Quartz glass has a series of excellent physical and chemical properties.

1. High temperature resistance. The softening point of fused quartz glass is about 1730℃ and can be used for long time working under 1100℃~1250℃. And working at 1450℃ in a short time.

2. Corrosion resistance. In addition to hydrofluoric acid, fused quartz glass is inert to other acids. Its acid resistance is 30 times as ceramic, 150 times as stainless steel. Especially, any other material cannot make a comparison with chemical stability of fused quartz at high temperature

3. The thermal stability is good. Thermal expansion coefficient is extremely small. And it can withstand severe temperature changes such that heating up to 1100℃ and putting it in normal temperature water will not crack.

4. The light transmittance is good. Quartz glass has good transmittance in the whole spectral band from ultraviolet to infrared. The transmittance of the visible light is above 95%. Especially in the ultraviolet spectrum band and the maximum transmittance is over 85%.

5. The electrical insulation performance is good. Resistance value of quartz glass equaling to 10000 times of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even under high temperature.

As a leading China fused quartz glass supplier and manufacturer, we are providing best price as well as quality for all kinds of customized fused quartz products. We are also willing to look for long term partners who are a distributor or wholesaler specialized in fused quartz glass in local.

For prompt quotation, please contact us at below form.