Quartz Glass Property:

MICQ supply three types of quartz glass materials: Fused Quartz/Synthetic Quartz Silica/IR Quartz. Through deep processing of the threes, and produced out any sizes/specification of quartz products for application in the field of industry, medical, lighting, laboratory, semiconductor, communications, optics, electronics, optics, aerospace, military, chemical, optical fiber, coating and so on.

•The three types of quartz materials have the same Mechanical/Physical Property:

| Property | Reference Value | Property | Reference Value |

| Density | 2.203g/cm3 | Refractive Index | 1.45845 |

| Compressive Strength | >1100Mpa | Coefficient of thermal expansion | 5.5×10-7cm/cm.℃ |

| Bending Strength | 67Mpa | Melting point temperature | 1700℃ |

| Tensile Strength | 48.3Mpa | The work temperature for a short time | 1400℃~1500℃ |

| Poisson’s Ration | 0.14~0.17 | The work temperature for a long time | 1100℃~1250℃ |

| Elastic Modulus | 71700Mpa | Resistivity | 7×107Ω.cm |

| Shearing Modulus | 31000Mpa | Dielectric Strength | 250~400Kv/cm |

| Mohs Hardness | 5.3~6.5(Mohs Scale) | Dielectric Constant | 3.7~3.9 |

| Deformation Point | 1280℃ | Dielectric absorption coefficient | <4×104 |

| Specific Heat(20~350 ℃ | 670J/kg ℃ | Dielectric loss coefficient | <1×104 |

| Thermal Conductivity(20℃) | 1.4W/m ℃ |

•Chemical Property(ppm):

| Element | Al | Fe | Ca | Mg | Yi | Cu | Mn | Ni | Pb | Sn | Cr | B | K | Na | Li | Oh |

| Fused

quartz |

16 | 0.92 | 1.5 | 0.4 | 1.0 | 0.01 | 0.05 | <0.3 | <0.3 | <0.3 | <0.3 | 0.2 | 1.49 | 1.67 | <0.3 | 400 |

| Synthetic Quartz Silica | 0.37 | 0.31 | 0.27 | 0.04 | 0.03 | 0.03 | 0.01 | <0.03 | <0.03 | <0.03 | <0.03 | <0.02 | 0.5 | 0.5 | <0.03 | 1200 |

| Infrared Optical quartz | 35 | 1.45 | 2.68 | 1.32 | 1.06 | 0.22 | 0.07 | <0.03 | <0.03 | <0.03 | <0.03 | 0.3 | 2.2 | 3 | 0.3 | 5 |

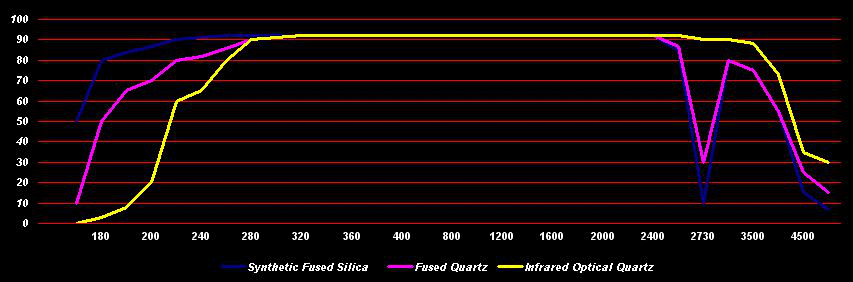

•Optical Property(Transmittance)%:

| Wavelength(nm) | Synthetic Fused Silica(JGS1) | Fused Quartz(JGS2) | Infrared Optical Quartz(JGS3) |

| 170 | 50 | 10 | 0 |

| 180 | 80 | 50 | 3 |

| 190 | 84 | 65 | 8 |

| 200 | 87 | 70 | 20 |

| 220 | 90 | 80 | 60 |

| 240 | 91 | 82 | 65 |

| 260 | 92 | 86 | 80 |

| 280 | 92 | 90 | 90 |

| 300 | 92 | 91 | 91 |

| 320 | 92 | 92 | 92 |

| 340 | 92 | 92 | 92 |

| 360 | 92 | 92 | 92 |

| 380 | 92 | 92 | 92 |

| 400-2000 | 92 | 92 | 92 |

| 2500 | 85 | 87 | 92 |

| 2730 | 10 | 30 | 90 |

| 3000 | 80 | 80 | 90 |

| 3500 | 75 | 75 | 88 |

| 4000 | 55 | 55 | 73 |

| 4500 | 15 | 25 | 35 |

| 5000 | 7 | 15 | 30 |

•Property Instruction:

- Purity: Purity is an important index of quartz glass. The content of SiO2 in ordinary silica glass is more than 99.99%. The content of SiO2 in high purity synthetic quartz glass is above 99.999%.

- Optical performance: Compared with ordinary silicate glass, the transparent quartz glass has excellent light permeability at the whole wavelength band. In the infrared and visible light spectrum region, the spectral transmittance of quartz glass is better than ordinary glass. In the ultraviolet spectral region especially short wave ultraviolet spectrum, the quartz glass is much better than the other.

- Heat resistance: The thermal properties of quartz glass include heat resistance, thermal stability, volatility at high temperature, specific heat and thermal conductivity, crystalline properties (also known as crystallization or permeability) and high temperature variability. The quartz glass thermal expansion coefficient is 5.5×10-7cm/cm ℃ as 1/34 of copper & 1/7 of borosilicate. These characteristics are used in the optical field of optical lens, high temperature window and some product requiring sensitivity to thermal changes to a minimum. Quartz glass as the expansion coefficient is small, it has a high thermal shock resistance, transparent quartz glass in a furnace at 1100 ℃ under heating 15 minutes, and then into the cold water, which can withstand 3-5 cycles without rupture. The softening point of quartz glass is very high like the transparent quartz glass is 1730 ℃, so the continuous use temperature of quartz instrument is 1100 ℃ -1200 ℃, 1300 ℃ can be used in a short time.

- Chemical performance: Quartz glass is good acid material. Its chemical stability is equivalent to 30 times of acid resistant ceramic, 150 times of nickel chromium alloy and common ceramic at high temperature and concentrated acid application superiority is particularly significant excepting hydrofluoric acid and 300 ℃ phosphate. The quartz glass cannot be eroded by other acid erosion, especially sulfuric acid, nitric acid, hydrochloric acid and aqua regia at high temperature.

- Mechanical property: The mechanical properties of quartz glass are similar to those of other glasses, and their strength depends on micro cracks in the glass. Modulus of elasticity, tensile strength and flexural strength increase with increasing temperature, usually reaching the maximum at 1050-1200 ℃. Recommended for user designs with compressive strength is 1.1 * 109Pa and ensile strength 4.8 * 107Pa.

- Electrical property: Quartz glass contains only trace amounts of alkali metal ions which is a poor conductor. Its dielectric loss is very small for all frequencies. As solid insulators, its electrical and mechanical properties are much better than those of other materials. At normal temperature, the intrinsic resistance of transparent quartz glass is 1019ohm cm, being equivalent to 103-106 times of ordinary glass. The insulation resistance of transparent quartz glass at normal temperature is 43 thousand volts/mm.

- Compressive resistance: Theoretically, the tensile strength is very high more than 4 million pounds per square inch, optical glass of the same thickness of anti-dynamic strength is 3~5 times of ordinary glass and bending strength is 2~5 times of ordinary glass. When the glass is damaged by external force, debris particles become an obtuse angle which reduce the harm to the human body.

- Homogeneity: The chemical composition is consistent with the physical state resulting to eliminate cracks, bubbles, impurities, turbidity, deformation and so on. In physically and chemically property, it has a high-level uniformity to ensure good performance.