Among the diverse materials utilized in lens fabrication, quartz glass emerges as a remarkable option due to its exceptional optical properties and distinct advantages. This article will explore the unique characteristics of quartz glass that render it an optimal material for lens production, elucidating its optical, mechanical, and thermal attributes as well as its significance across various optical applications.

- Optical purity and transparency

Quartz glass is renowned for its exceptional optical purity and transparency, securing a preeminent position in the domain of lens fabrication. Its intrinsic clarity minimizes light absorption and dispersion, thereby ensuring high transmittance across a broad spectrum of wavelengths. This characteristic is vital for applications such as microscopy, photography, and astronomy that demand precise imaging and accurate color reproduction. By harnessing the unparalleled optical clarity of quartz glass, lens manufacturers can attain superior image resolution and fidelity, thereby facilitating advancements in scientific research and industrial inspection processes.

- Thermal stability and resistance to environmental factors

Another notable advantage of quartz glass lies in its exceptional thermal stability and resistance to environmental factors. In contrast to conventional glass materials, quartz glass demonstrates minimal thermal expansion, rendering it highly resilient to temperature fluctuations and thermal shock. This intrinsic stability is particularly beneficial for optical systems operating under extreme conditions, such as high-temperature industrial processes or space exploration missions. Furthermore, quartz glass exhibits excellent resistance to chemical corrosion, moisture, and radiation, thereby ensuring longevity and reliability in harsh environments. These attributes render quartz glass lenses indispensable across a multitude of applications including laser optics, semiconductor manufacturing, and aerospace engineering.

- Mechanical strength and durability

In addition to its optical and thermal properties, quartz glass exhibits excellent mechanical strength and durability, rendering it an optimal material for use in demanding lens applications. Quartz glass lenses display a high Young’s modulus and tensile strength, along with remarkable resistance to mechanical stress and deformation, which ensure the dimensional stability and accuracy of optical components. The robustness enables quartz glass lenses to withstand rigorous handling and environmental pressures, rendering them suitable for deployment in harsh industrial environments and outdoor optical systems. Furthermore, the inherent hardness of quartz glass serves to mitigate the abrasion and scratches on its surface, thereby preserving the integrity of its optical properties and reducing the necessity for prolonged maintenance.

- Low dispersion and aberration correction

Quartz glass is further distinguished by its exceptional low dispersion properties, which facilitate precise correction of chromatic aberrations within optical systems. Its unique refractive index dispersion curve enables quartz glass lenses to effectively mitigate color fringing and spectral distortion, thereby enhancing image clarity and sharpness. This characteristic is indispensable in applications demanding high-fidelity imaging and accurate color reproduction, such as high-resolution cameras, medical imaging devices, and projection systems. The capacity to optically manage chromatic aberrations inherent in quartz glass ensures unparalleled image quality and consistency, thus promoting advancements across diverse fields ranging from medical diagnostics to cinematography.

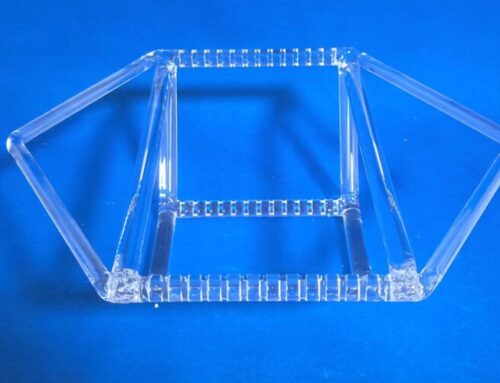

- Manufacturing flexibility and versatility

One of the primary advantages of quartz glass in lens manufacturing lies in its exceptional flexibility and versatility. Quartz glass can be precisely molded and polished to meet exact specifications, facilitating the creation of intricate lens geometries and customized optical designs. This adaptability empowers lens designers to optimize optical performance tailored to specific application requirements, allowing for precise customization of characteristics such as focal length, aperture, and field of view. Furthermore, quartz glass can be treated with a variety of anti-reflective and protective coatings to enhance both optical performance and durability. Such versatility has rendered quartz glass lenses indispensable across numerous industries, including telecommunications, automotive engineering, medical device manufacturing, and consumer electronics.

In conclusion, the advantages associated with utilizing quartz glass for lens fabrication are manifold—encompassing superior optical purity, thermal stability, mechanical strength, aberration correction, and manufacturing flexibility.