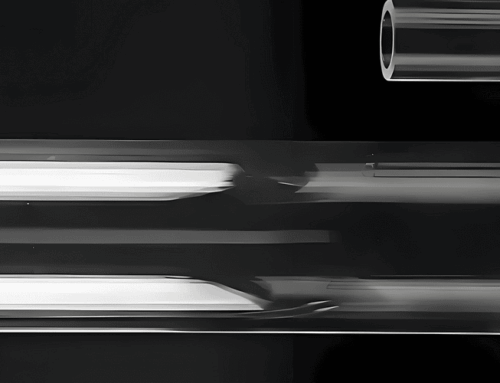

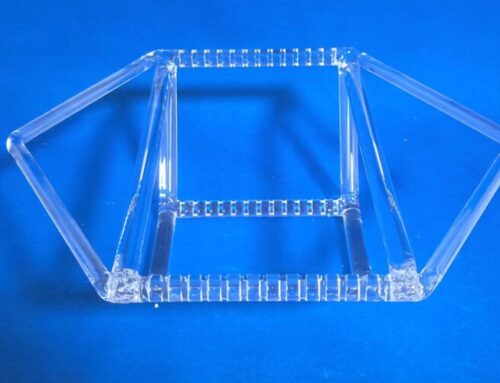

There are various types of quartz glass products in the industrial field. Different types have different uses. One of its uses is as a quartz liner. The use of large-sized quartz cylinders or container as quartz liners poses certain operational difficulties. The dimensional tolerance requirements for the entire cylinder are quite strict. Especially, the requirements for the flatness of the quartz container flange are extremely strict. A slight unevenness can lead to sealing problems. Therefore, quartz liners should be processed strictly according to the drawing requirements. The welding process of large-sized quartz square container liner is particularly important. Welding at an overheated temperature may cause deformation of the flange plane. If the deformation is too severe, it will lead to irreparable damage. Invert the completed quartz glass liner and place it in a grinder for overall flange flatness repair. This operation can ensure the flatness of the entire flange section.