Classification of Quartz Crucibles

In recent years, the quartz crucible industry in China has experienced rapid development. The quartz crucible, crafted from high-purity quartz sand, boasts exceptional cleanliness, homogeneity, and high-temperature resistance. It is currently extensively utilized in the production processes of crystalline silicon extraction within the solar and semiconductor industries.

This article presents a comprehensive classification of quartz crucibles based on various categorization methods.

- According to the application, quartz crucible can be divided into: semiconductor (electronic grade) quartz crucible, photovoltaic (solar grade) quartz crucible.

Semiconductor quartz crucible is mainly employed for the growth of semiconductor single crystalline silicon, which is used to manufacture integrated circuits, microelectronics devices, etc. Photovoltaic quartz crucible is mainly employed for the growth of photovoltaic single crystalline silicon, which is used to manufacture solar cells, photovoltaic modules, etc.

The semiconductor quartz crucible necessitates higher purity, typically requiring SiO2 purity exceeding 99.998%, impurity content below 10ppm, and gas-liquid inclusion content under 100ppm. In contrast, the photovoltaic quartz crucible has relatively lower purity requirements, generally mandating SiO2 purity above 99.95%, impurity content below 100ppm, and gas-liquid inclusion content under 500ppm.

The semiconductor quartz crucible generally uses synthetic quartz as the inner layer and natural quartz as the outer layer, with a transition layer between the inner and outer layers to improve the strength and stability of the crucible. In contrast, the photovoltaic quartz crucible generally uses natural quartz as the inner and outer layers, where the inner layer representing a bubble-free layer and the outer layer is a bubble composite layer, in order to improve the temperature resistance and heat preservation of the crucible.

The semiconductor quartz crucible is generally small, between 8-12 inches in diameter and 20-30 cm in height; The photovoltaic quartz crucible is generally large, with a diameter between 24-40 inches and a height between 40-60 cm.

- According to the typesof inner quartz, quartz crucibles can be divided into: synthetic quartz crucible (SQC), natural quartz crucible (NQC).

The raw materials for quartz crucibles can be broadly divided into two types, one is the natural quartz sand and the other is the high purity synthetic quartz.

The inner surface of the synthetic crucible has higher purity and is suitable for the drawing of high-grade silicon rods; Natural quartz crucible with crystallized inner surface, is suitable for multiple feeding processes and long time use.

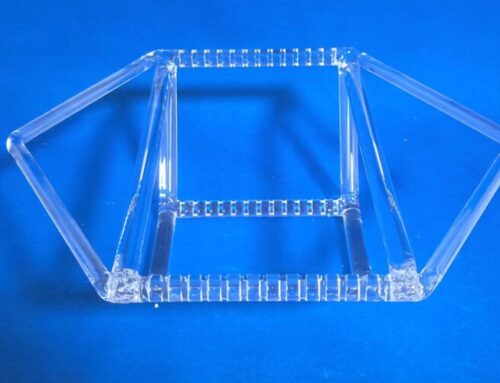

- According to the shapes, quartz cruciblescan be divided into: round quartz crucible, square quartz crucible.

Square quartz crucible is used for the casting of polycrystalline silicon ingot; Round quartz crucible is used in the drawing process of single crystalline silicon rods.

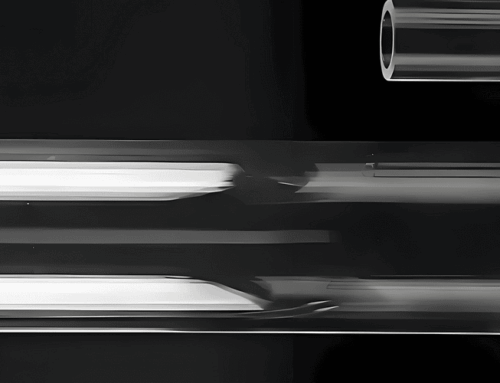

- According to the different molding process, quartz cruciblescan be roughly divided into: injection molding quartz crucible, extrusion molding quartz crucible.

The main moulding methods for quartz crucibles are extrusion moulding and injection moulding. In extrusion moulding, the quartz powder is extruded through the extrusion press to form the shape and size of the crucible; In injection moulding, the quartz powder is mixed with an organic binder and injected into the mould.

- According to the appearance of quartz crucible, itcan be divided into: transparent quartz crucible, opaque quartz crucible.

The earliest quartz crucibles are all transparent. The structure of this transparent crucible is easy to lead to uneven heat transfer, increasing the difficulty of crystal rod growing, so the transparent crucible is eliminated later.

At present, the dominant quartz crucible on the market is the translucent quartz crucible. The advantages of the translucent quartz crucible include high purity, high temperature resistance, large size, high precision, good heat preservation, energy saving, stable quality, etc.