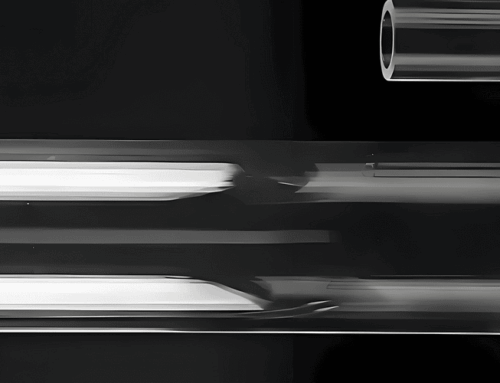

For thermal processed quartz glass products such as quartz tubes, quartz instruments, quartz cylinders, etc., it is necessary to clean the raw materials and finished products before and after thermal processing. Pre processing cleaning is mainly to prevent external impurities from infiltrating the surface of quartz glass in high-temperature environments. Common impurities include white frost like impurities and black particulate impurities. There is also a special situation where the quartz tube wall, which is itself clean, undergoes discoloration such as browning at high temperatures. This situation is because the purity of the quartz material itself is not purity enough, and the content of other elements exceeds the standard. After thermal processing, the surface of the finished quartz usually presents a white frost like substance. At this point, it can be removed by polishing with a high-temperature hydrogen oxygen flame. Alternatively, acid washing can be carried out later.

During the cleaning process, the water quality we use is obtained through multiple layers of filtration. This type of water quality can effectively reduce the formation of impurities during thermal processing.