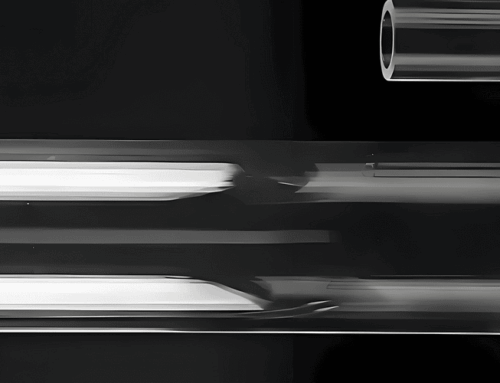

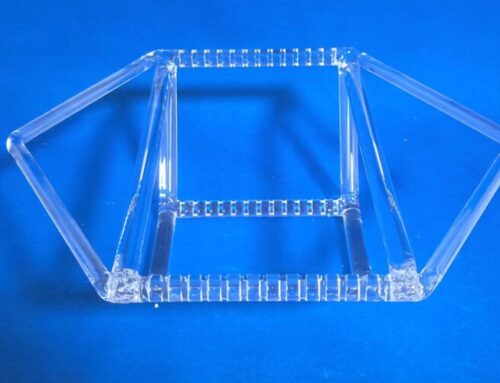

Synthetic quartz glass material (JGS1) is a high-purity fused silica quartz glass material. It is a new type of quartz glass raw material used for optics and heating in industry. It is also the quartz material with the highest silica purity in quartz materials, which can generally reach more 99.999% or SiO2.

Material specific processing: This processing is actually a secondary purification process and also a reduction process. The purpose is to increase the purity of SiO2.

1. Through special processes, the original quartz ore is melted at high temperature and purified into relatively pure silica with a general purity of over 99.5% SiO2.

2. Chlorine gas and purified SiO2 undergo a chemical reaction at high temperatures (around 1000 ℃), which removes various other non silica impurities and forms high-purity silicon tetrachloride (SiCl4).

3. Using high-purity silicon tetrachloride (SiCl4), hydrogen (H2), and oxygen (O2), a chemical reaction is initiated by heating again to generate the final high-purity quartz (with a purity of over 99.999% SiO2).

Material chemical, optical, and physical properties:

Good transparency (belonging to the category of far ultraviolet optical quartz glass, with an application spectral band range of 0.185-2.5) μ m) , high temperature resistance (softening point temperature is about 1730 ℃), corrosion resistance (except hydrofluoric acid, quartz glass hardly reacts with other acid substances), good thermal stability (extremely small coefficient of thermal expansion of glass, can withstand severe temperature changes), good electrical insulation performance (the resistance value of quartz glass is 10000 times that of ordinary glass, which is an excellent electrical insulation material).