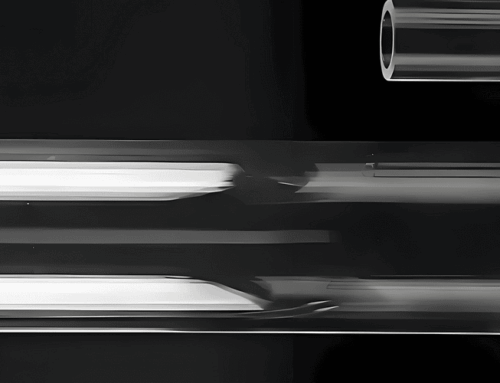

1.Electric fused transparent quartz glass

It is by the electric resistance heating element in the vacuum pressure furnace melting ordinary crystal, through artificial or mechanical pull made of various quartz tubes.These products can be processed into a variety of instruments.This kind of glass is the most commonly used in quartz glass.It can meet the needs of most high temperature resistance, corrosion resistance, resistance to electrical breakdown occasions.

The different performance of electric fused transparent quartz glass make different uses, and the model is divided into DTS2/DTS1/DTS3/DSQ/DSY.

2.Gas refining transparent quartz glass

Gas refining transparent quartz glass is made by melting high crystal powder with oxyhydrogen flame.It has excellent chemical properties, thermal properties, electrical properties, to become more valuable in the quartz glass products.This kind of quartz glass is widely used in semiconductor, electronic industry and other engineering technology.The quartz glass can be made into all kinds of pipes, the crucible drawing for single crystal silicon, and a variety of large-scale instrument vessel distillation tower etc.

According to the performance characteristics, its model can be divided into QTS1.2/QTG1.2/QSQ/QSY.

3.electric arc process quartz glass

It is with high pure crystal powder as raw material, as special quartz glass melted by producing electric arc heat source of a group of high purity special graphite electrodes under AC or DC voltage.In the world, the quartz glass is widely used in semiconductor industry of crucible drawing single crystal, polycrystalline silicon lining etc..Its characteristic is that the inner wall is smooth, transparent, the outer wall scrub is opaque, good thermal insulation performance. when the temperature field is uniform, the purity is higher than the gas refining process of quartz glass, large size, can be done in diameter 500MM.At the same time, its production cost is low, the price is lower than the same use standard product 30%.

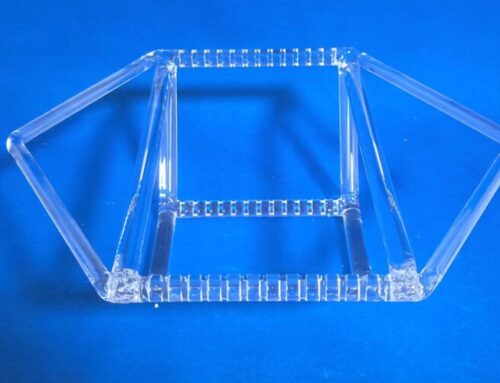

4.High purity synthetic quartz coated quartz glass products

At present the world for semiconductor used in the production of quartz glass, can be divided into two kinds according to its purity. One is the natural crystal as raw material to melt into the product.Impurity content is generally around 50ppm.The other is to use high purity synthetic raw materials (such as four chlorinated silicon, etc.) through the high temperature hydrolysis melt made products.His purity is very high, the total content of impurities is generally not more than 2ppm, but its price is expensive.Its biggest drawback is that the softening point is about 80 lower than that of the crystal.The crucible and diffusion tube made of it are easy to deform in the process of using.

In order to meet the needs of the semiconductor industry,and make full use of the characteristics of low cost, high softening point and high purity of synthetic quartz.Our factory has successfully developed a high purity silica coated quartz glass products.This product is made of quartz crystal glass wall with high temperature spraying process method, coated with a layer of pure synthetic quartz glass.The product has two kinds of characteristics of quartz glass products.Our factory can increase the weight of coating according to the customer’s requirement, and meet the special demand.