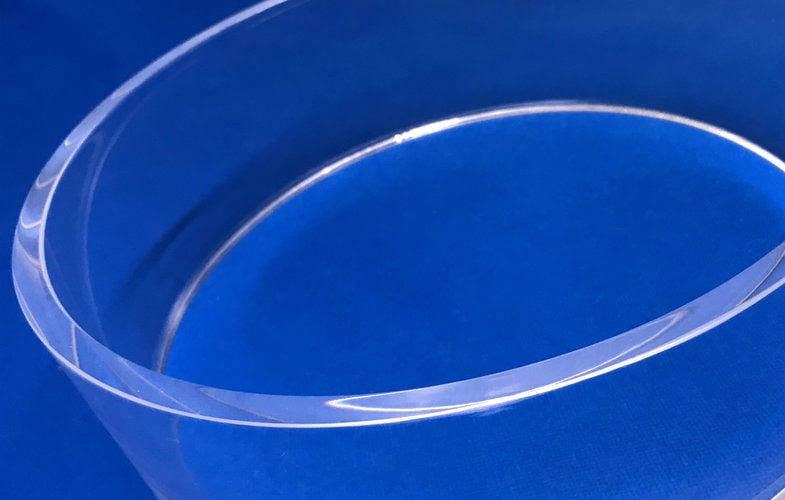

The quartz flange ring serves as a high-performance component for pine connections, with its selection and installation processes directly influencing the tightness and stability of the whole system. The correct selection and installation method is crucial for optimizing the performance of the quartz flange ring and preventing leakage.

When selecting a quartz flange ring, it is imperative to consider factors such as working pressure, temperature, medium characteristics, and connection dimensions of the pipeline. Quartz flange rings are available in various specifications and models, including flat, convex, and flanged types, with each tailored for specific application. For pipelines subjected to high working pressures, high temperatures, or strong corrosive medias, it is advisable to select quartz flange rings that exhibit higher strength and superior corrosion resistance. Additionally, ensuring compatibility between the connection size of selected flange ring and the size of pipeline is essential, to prevent installation challenges or inadequate sealing due to dimensional discrepancies.

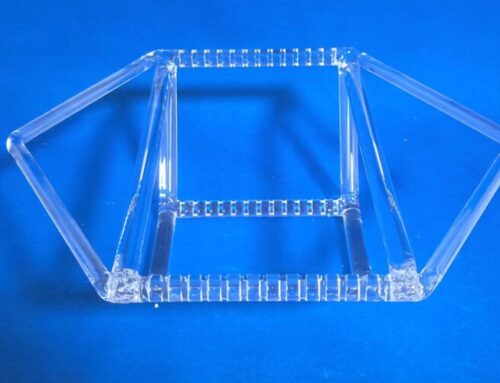

Prior to installation, both the quartz flange ring and its corresponding connecting pipe should undergo thorough inspection to confirm that their surfaces are free from damage, cracks, or contaminants. During installation procedures, the flange ring should be tightly fitted to the pipe end first, and then secured with appropriate bolts and nuts. Throughout this fastening process, adherence to principles of symmetry and uniformity while gradually increasing fastening force will mitigate risks of deformation or damage resulting from excessive tightening at one time.

In order to guarantee the effective sealing of the system, it is essential to pay close attention to the following points: firstly, the sealing surface of the flange ring must be kept free from contamination and in a dry state, in order to prevent the introduction of impurities or moisture which could compromise the integrity of the seal; Secondly, it is imperative that the bolts and nuts are made from the same material as the flange ring in order to prevent corrosion or loosening caused by material inconsistency; Thirdly, the connection status of the flange ring is subject to regular examination. In the event of any loosening or leakage, it is of the utmost importance to tighten or replace the relevant component.

In essence, the selection and installation of the quartz flange ring represents a pivotal stage in guaranteeing the tightness of the system. An appropriate selection and installation process can enhance the stability and safety of the system, extend the lifespan of the equipment, and reduce maintenance costs. Accordingly, during the actual operation, it is imperative to adhere to the specifications meticulously to guarantee that each step is precise.