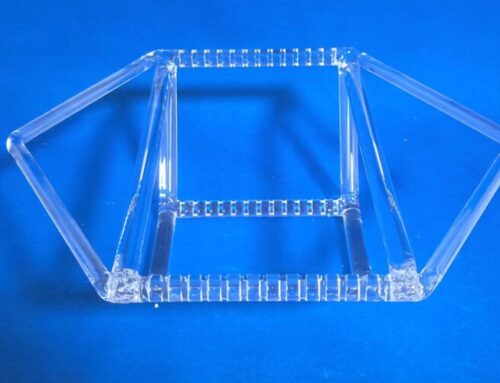

Quartz glass is a special industrial technology glass comprising a single component of silica. High-purity opaque quartz glass represents a significant category of quartz glass, offering notable advantages over ordinary quartz glass in terms of purity, thermal resistance and chemical erosion resistance. Additionally, it exhibits a distinctive thermal insulation performance. This can be attributed to the uniform dispersion of a large number of micron bubbles within the material, which can increase the scattering of thermal radiation within the material and effectively prevent heat loss. In industry, it is frequently used as a thermal insulation material for reaction chambers in semiconductor, photovoltaic and other manufacturing equipment. By reducing the outward loss of heat from the chamber, this thermal insulation can contribute to cost savings and lifespan extending of the heating components.

In recent years, Chinese quartz glass production enterprises have successfully mastered advanced production processes through technical researches, resulting in a notable improvement in product quality and meeting international advanced standards. The accelerated advancement of Chinese semiconductor, optical communication, solar photovoltaic, and aerospace industry has led to a corresponding increase in demand and output for high-purity opaque quartz glass, a crucial auxiliary material for those industries.

Raw material requirements

The use of opaque quartz glass in both photovoltaic and semiconductor industries necessitates the attainment of high purity standards. In comparison to the photovoltaic industry, the semiconductor industry imposes more exacting material purity requirements.

The preparation of semiconductor materials and devices necessitate an extended period of time and high temperatures. As these processes are conducted in quartz glass instruments and utensils, any quartz glass impurities exceeding the standard will spread to the semiconductor materials and devices, which will inevitably lead to contamination of the semiconductor materials and devices.

High-purity opaque quartz glass for semiconductor industry requires that the total amount of the following 16 kinds of impurity elements do not exceed 20 micrograms/g, including: aluminum (Al), ferrum (Fe), calcium (Ca), magnesium (Mg), titanium (Ti), copper (Cu), cobalt (Co), nickel (Ni), manganese (Mn), lithium (Li), sodium (Na), potassium (K), boron (B), barium (Ba), chromium (Cr), and zirconium (Zr). The total amount of those 16 impurity elements in photovoltaic industry high-purity opaque quartz glass should not exceed 30 micrograms/g.

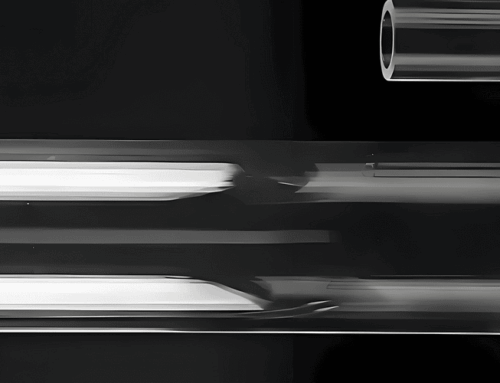

Preparation methods

The preparation of quartz glass can be subdivided according to different heat sources and processes involved. These include electric melting, gas refining, plasma melting, etc. Among these, the electric melting method has the advantage of high yield and economy, and is therefore the most common process method in China. The yield of the electric melting method depends on both the process and the raw materials used.

Manufacturing Procedures

- Break the quartz glass and screenit to obtain fine quartz sand particles;

- Add the fine quartz sand particles and deionized waterinto the ball mill for wet grinding to obtain the slurry.

- Remove the grinding ball from the slurry, and put lactic acidinto the slurry, rotating and homogenizing it until there is no significant settlement.

- Injectthe slurry into the mold, and obtain a porous green body after dehydration and removing it from the mold.

- Leavethe green body stand, making it dry at a constant temperature.

- Obtain thefinished product by sintering the dried green